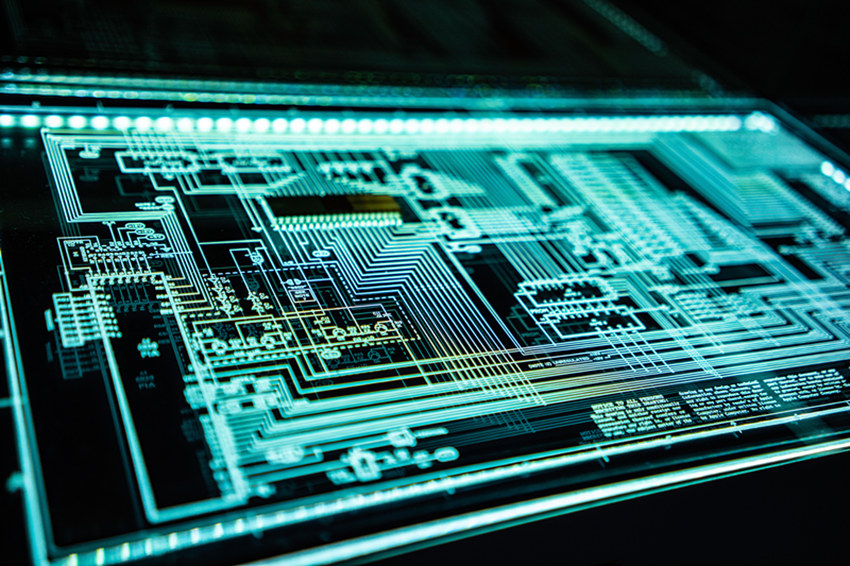

Surface Mount Technology (SMT) has already revolutionized the world of electronics manufacturing, but its journey is far from over. As technology continues to evolve at an astonishing pace, the future of SMT holds exciting possibilities, especially with the integration of 3D printing in PCB assembly.

In this article, we will delve into the captivating world of 3D printing and its impact on next-generation PCBs, as SMT paves the way for innovative and cutting-edge electronic devices.

3D Printing: A Game-Changer in PCB Manufacturing

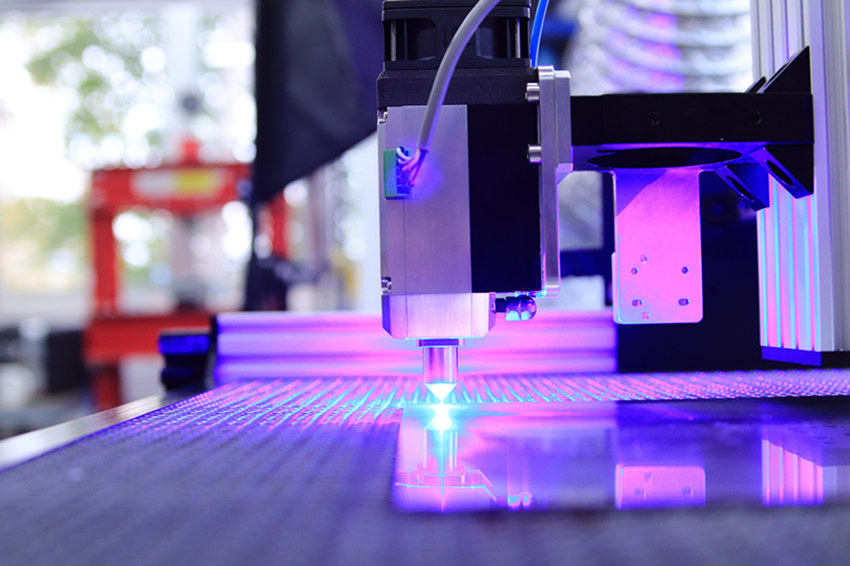

The emergence of 3D printing technology has sparked a paradigm shift in various industries, and PCB manufacturing is no exception. Traditional PCB fabrication involves multiple complex steps, from designing and etching copper traces to drilling holes and applying solder masks. However, 3D printing offers a revolutionary approach, enabling the direct printing of PCBs layer by layer, eliminating the need for several intermediate processes.

Seamless Integration of Components

In the realm of SMT, 3D printing brings a whole new level of design flexibility and component integration. The ability to print conductive traces and insulating layers simultaneously allows for intricate and compact designs. Components can be seamlessly integrated into the PCB during the printing process, reducing assembly time and potential points of failure.

Customization and Prototyping Made Effortless

Gone are the days of lengthy and expensive PCB prototyping. With 3D printing in SMT, engineers can rapidly iterate designs and produce customized PCBs with ease. This agile prototyping approach enables quicker testing and validation of new ideas, accelerating the product development cycle.

Enhanced Heat Dissipation and Mechanical Strength

3D-printed PCBs offer the advantage of optimized heat dissipation and improved mechanical strength. Designers can create complex internal structures that efficiently dissipate heat, enhancing the reliability and performance of electronic devices. Moreover, lightweight yet robust materials can be chosen to strike the perfect balance between functionality and durability.

The Intersection of SMT and 3D Printing in Realizing IoT Devices

The Internet of Things (IoT) has opened up a world of interconnected devices, and SMT combined with 3D printing is the perfect match for realizing the full potential of IoT devices. The compact and integrated designs enabled by 3D printing allow for smaller, energy-efficient IoT devices that seamlessly fit into our daily lives.

Challenges and Future Prospects

As with any technological advancement, there are challenges to overcome. Material compatibility, printing resolution, and ensuring reliable conductive traces are some of the hurdles that need to be addressed for the widespread adoption of 3D-printed PCBs in SMT. However, ongoing research and development hold the promise of overcoming these obstacles.

The convergence of Surface Mount Technology (SMT) and 3D printing is set to redefine the landscape of PCB manufacturing. With the potential for agile prototyping, customized designs, and enhanced functionality, this synergy is paving the way for a new era of electronic devices. As the future unfolds, the magic of SMT and 3D printing will continue to unleash innovations that shape our digital world.

Discover the forefront of SMT with TXJ, China’s renowned leader in electronic manufacturing services. Our cutting-edge solutions, customer-centric approach, and expert team await your collaboration. Contact us at [email protected] or visit www.txjpcb.com to shape the future of SMT together!