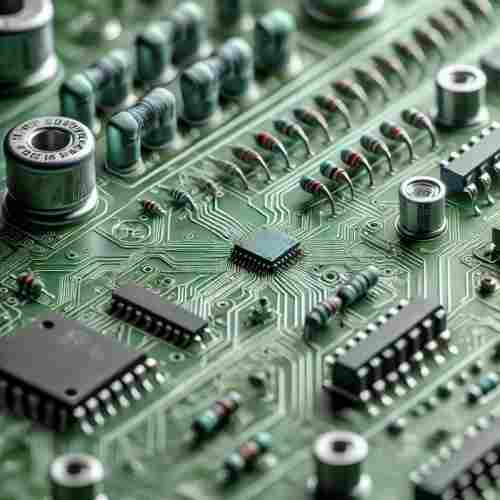

Optimizing SMT Assembly Design for Enhanced Performance

Surface Mount Technology (SMT) has revolutionized the electronics industry by enabling the miniaturization of electronic devices and improving circuit performance. Effective SMT assembly design is crucial for ensuring high-quality, reliable, and cost-efficient manufacturing. This article outlines key considerations and best practices for optimizing SMT assembly design. 1. PCB Design and Layout The foundation of successful […]

Optimizing SMT Assembly Design for Enhanced Performance Read More »