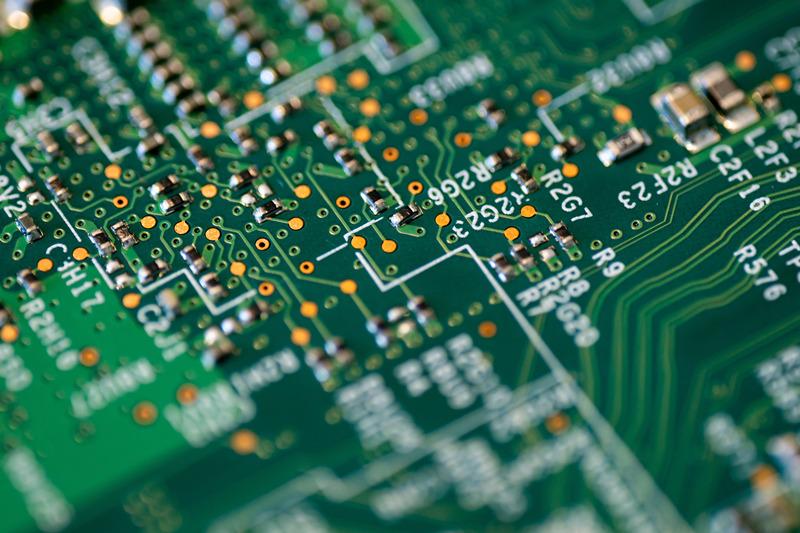

Reflow SMT, part of Surface Mount Technology (SMT), revolutionizes electronic manufacturing. It directly places components on printed circuit boards (PCBs), eliminating traditional through-hole assembly.

In Reflow SMT, components like chips, resistors, and capacitors connect securely through melted solder paste at high temperatures. This paste, often tin-lead or lead-free alloy, ensures reliable conductivity.

The process involves stencil printing for precise solder paste application, automated component placement, controlled-temperature reflow soldering, and cooling for solidification. This ensures precise connections and enhances electrical performance.

Reflow SMT offers high integration and density, improving device performance and reliability. It addresses common soldering issues found in traditional through-hole assembly, such as solder bridges and short circuits. Ongoing innovations, like lead-free soldering, align with evolving environmental considerations.

In summary, Reflow SMT is pivotal for efficient and reliable high-performance electronic device production in modern electronic manufacturing.