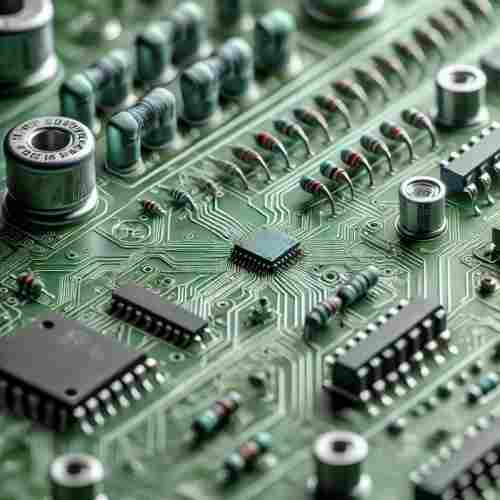

Surface Mount Technology (SMT) has become a cornerstone of modern electronics, enabling the efficient assembly of components onto printed circuit boards (PCBs). SMT contract manufacturing, or EMS (Electronics Manufacturing Services), plays a crucial role in the electronics industry by offering specialized services for PCB assembly.

What is SMT Contract Manufacturing?

SMT contract manufacturing involves outsourcing the assembly of electronic components to a third-party service provider. This includes the placement of surface mount devices (SMDs) onto PCBs, soldering, inspection, and testing. The primary advantage of SMT contract manufacturing is that it allows companies to leverage specialized expertise and equipment without investing in expensive in-house machinery.

Key Benefits

- Cost Efficiency: By outsourcing SMT assembly, companies can reduce capital expenditures on equipment and facilities, as well as lower labor costs.

- Expertise and Quality: EMS providers have specialized knowledge and experience, which can lead to higher quality and more reliable products.

- Scalability: Contract manufacturers offer flexible production scales, allowing businesses to easily adjust volumes based on demand.

- Faster Time-to-Market: With established processes and efficient production lines, EMS providers can expedite the manufacturing process, helping companies get their products to market faster.

Choosing an SMT Contract Manufacturer

When selecting an SMT contract manufacturer, it’s essential to consider several factors:

- Technical Capabilities: Ensure the provider has the necessary technology and expertise for your specific needs.

- Quality Control: Look for certifications and a strong track record in quality assurance.

- Cost and Lead Times: Evaluate pricing structures and delivery timelines to align with your budget and schedule.

- Communication and Support: Effective communication and support are crucial for addressing issues and ensuring smooth production.