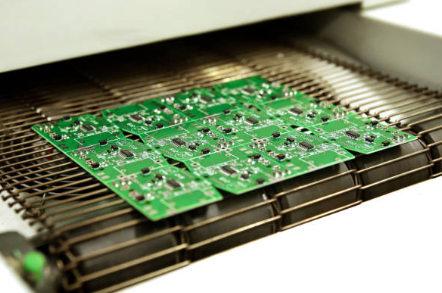

To maximize efficiency and productivity in a surface mount technology (SMT) manufacturing facility, it’s essential to implement the best practices for SMT line balancing and optimization:

- Component Sequencing: Arrange components in the order they are placed on the PCB, reducing machine setup time and improving overall throughput.

- Machine Placement Strategies: Utilize machine placement strategies that minimize idle time, such as group technology or parallel placement.

- Feeder Management: Maintain well-organized and properly stocked feeders to minimize changeover time and component shortages.

- Workflow Design: Optimize the workflow layout to minimize material handling, reduce operator movement, and enhance overall efficiency.

- Continuous Monitoring: Implement real-time monitoring and data analytics to identify bottlenecks and make data-driven decisions for process improvement.

Implementing these best practices will result in a more efficient and productive SMT assembly line.